The performance of a toothbrush is largely determined by the material and structure of its bristles, commonly referred to as toothbrush yarn in the manufacturing industry. While design, handle ergonomics, and head shape are important, the yarn directly affects cleaning efficiency, durability, and user comfort. Over the years, several materials have been developed for toothbrush bristles, with nylon and PBT (polybutylene terephthalate) being the most widely used. Recently, alternative materials such as biodegradable yarns, polyester, and specialized coatings have also gained attention in response to growing demand for sustainable and health-oriented products.

Understanding the differences among these yarn types is crucial for manufacturers, dentists, and consumers seeking the right balance of cleaning power, durability, and comfort.

Nylon, particularly Nylon 6 and Nylon 6.12, is one of the oldest and most widely used materials for toothbrush yarn. It is valued for its strength, flexibility, and cost-effectiveness.

Nylon remains the dominant choice for everyday manual toothbrushes and is suitable for consumers seeking an affordable and versatile option.

PBT, or polybutylene terephthalate, is a polyester-based material increasingly used as an alternative to nylon. It offers improved resilience and lower water absorption.

PBT is commonly used in premium toothbrushes, children’s brushes, and specialty oral care products for sensitive teeth.

Polyester yarn is sometimes used in toothbrush bristles, offering good chemical resistance and moderate stiffness. However, it is less common due to limited flexibility compared to nylon and PBT.

With growing environmental awareness, biodegradable alternatives like PLA (polylactic acid) or bamboo-based filaments are being developed. These aim to reduce plastic waste but face challenges such as limited durability and higher production costs.

Some toothbrush yarns are coated with silver, zinc, or antibacterial agents to reduce microbial buildup. While not a material in itself, coatings improve hygiene but may wear off over time.

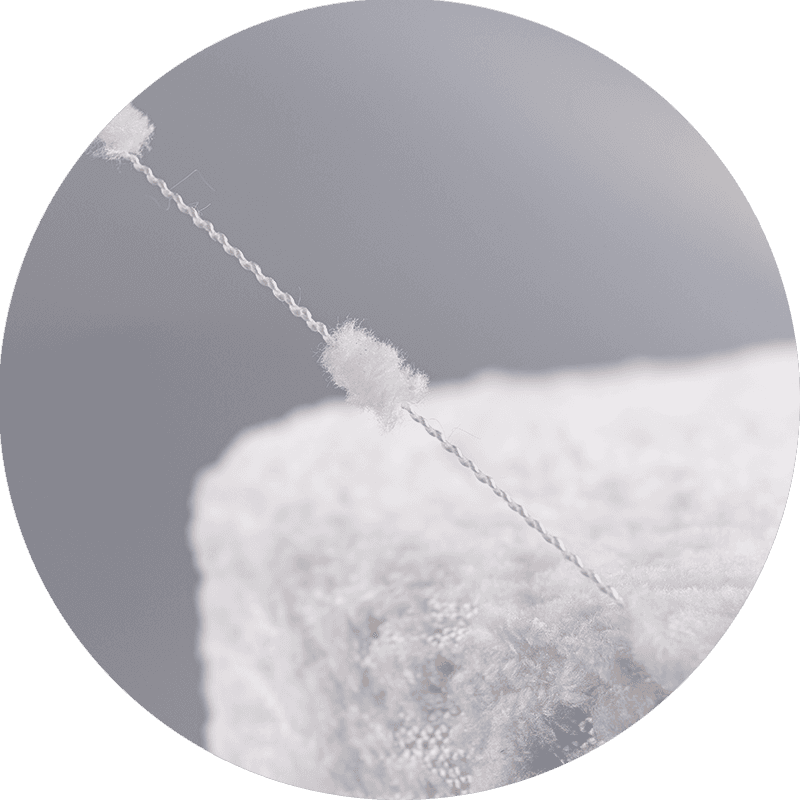

Modern manufacturing allows yarns to be tapered to ultra-fine tips for deeper cleaning between teeth and along the gumline. These yarns may use nylon or PBT as a base material, enhanced with special processing.

The choice between nylon, PBT, or alternative materials depends on user needs:

Manufacturers often combine different yarns or bristle shapes within a single toothbrush to balance cleaning efficiency, gum protection, and cost.

As sustainability and oral health awareness grow, toothbrush yarn technology is evolving. Future trends include:

These developments reflect a shift toward eco-friendly, health-conscious, and performance-driven toothbrush materials.

Toothbrush yarn plays a vital role in determining the effectiveness, comfort, and lifespan of a toothbrush. Nylon remains the most popular choice due to its strength, affordability, and versatility, while PBT is preferred in premium brushes for its softness, low water absorption, and hygienic qualities. Emerging alternatives, including biodegradable yarns and antibacterial coatings, are expanding consumer options in line with sustainability and health trends.

Ultimately, the choice between nylon, PBT, and other yarn types depends on individual needs—whether it is durability, gum sensitivity, environmental concerns, or budget. By understanding these differences, both manufacturers and consumers can make informed decisions, ensuring toothbrushes deliver effective and comfortable oral care.